| Material | Capacity | Diameter + Stairs | Length + Stairs | Weight |

|---|---|---|---|---|

| 9 Ga | 10000L/3200G | 79” | 125” + 18” | 4600lbs. |

| 9 Ga | 15000L/3300G | 79” | 188” + 18” | 6000lbs. |

| 3/16” | 18000L/4000G | 84” + 36” | 201” + 26” | 8000lbs. |

| 3/16” | 25000L/5500G | 99”+ 36” | 201”+ 26” | 9500lbs. |

| 3/16” | 35000L/7700G | 99”+ 36” | 281”+ 26” | 11500lbs. |

| 1/4” | 50000L/11000G | 118”+ 36” | 279”+ 26” | 18000lbs. |

| 1/4” |

60000L/13000G |

118”+ 36” |

336”+ 26” |

21000lbs. |

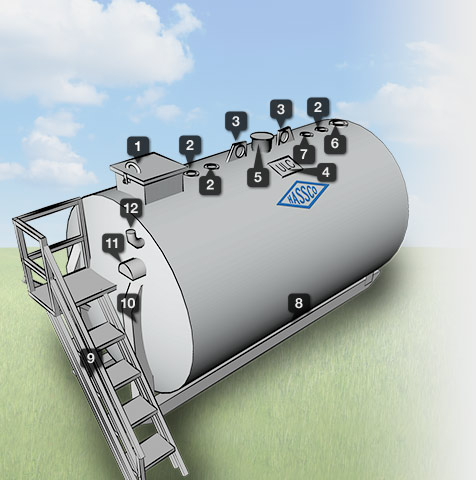

General Information

HASSCO’s aboveground storage tanks are manufactured with North American hot-rolled steel & meets or exceeds ULC specifications. Our vacuum monitored tanks will provide safe fuel containment for years to come. Tanks include standard post beam supports with stairs & platform. Emergency venting, spill box, fill cap & vacuum gauges are all standard. Available in single wall or double wall configurations. Double-wall tanks successfully comply with secondary containment requirements, therefore, removing the need for dyking systems. All tanks are blast cleaned before applying one coat epoxy primer and two coats premium topcoat finish. Powder coatings are available.

Downloads

Here are the downloads available for our line of Vacuum Monitored Tanks Double-Wall

Options

- Tank gauges, alarms, liners, heaters, and pumping & card-lock systems

- Vehicle barrier systems and catwalks

- Customized to your specifications as needed

- Single wall version available

Options

- Up to 60 000L/13 000G

Conformity

- ULC S601